BuWizz MOC series

Dakar racer

DESIGNED

2025

INVENTORY

1000 parts

THEME

SUV

INSTRUCTIONS

Download

BuWizz APP PROFILE

Coming soon

Following the success of the 4×4 Trophy Truck, I wanted to challenge myself to create a more efficient, compact, and structurally rigid off-road vehicle using the latest Technic components. With several new and improved parts available, this was the perfect opportunity to refine and evolve the design philosophy behind my earlier builds.

The BuWizz Dakar Racer combines lower weight, improved suspension geometry, and a simplified driveline — all while maintaining the raw power and responsiveness expected from a BuWizz-powered creation.

BuWizz

The Fastest brick

Video

1. Comparison and improvements with regard to the 4×4 Trophy Truck.

Before starting the project, I set myself a few goals and improvements compared to the 4×4 Trophy Truck.

- Reduced weight and part count. This version would use around a third fewer parts than the 4×4 Trophy Truck – 1000 compared to 1500

- Reduced the number of electronic components. Dakar would use 4 BuWizz Motors and 2 BuWizz 3.0 Pro bricks compared to Trophy Truck’s 6 BuWizz Motors, and 3 BuWizz 3.0 Pro bricks.

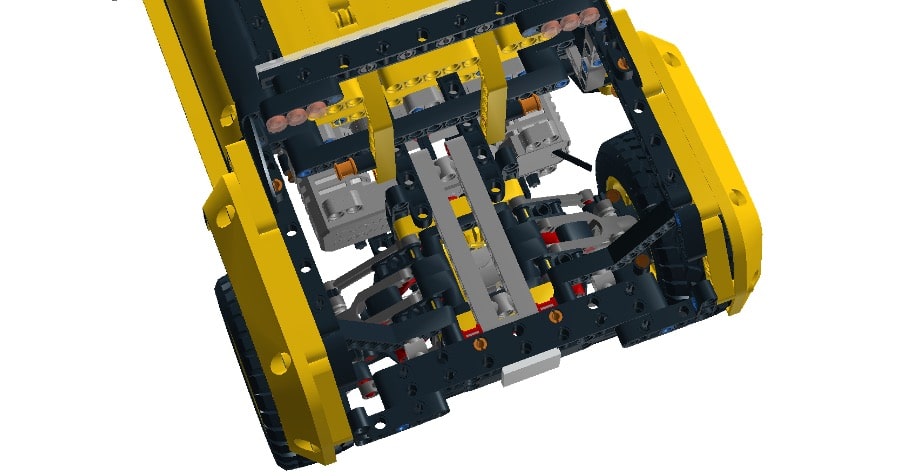

- Improved suspension system. First, the troublesome and unstable rear live axle suspension system would be replaced by independent suspension system. This allows me to lower the support frame as low as possible, therefore improving stability when cornering and improving stiffness. The suspension geometry would also be improved to give a progressive suspension response.

- Improved steering system. Steering arms to be lengthened and both steering racks motorized with the same PU L motor. This reduces the slack in the steering system, improves the accuracy of the steering system and increases robustness.

- Easier access for charging. BuWizz bricks are to be placed in such a position to give them easy access for turning off and charging.

- Easy to replicate. Use commonly available elements in order to create instructions so anyone can replicate the model. This means getting rid of 9L shock absorbers, old front steering hubs, etc.

2. Building the digital model prototype

As with all my projects, I first start building a digital model. For this project, I wanted to reuse as many of the existing components I had readily available.

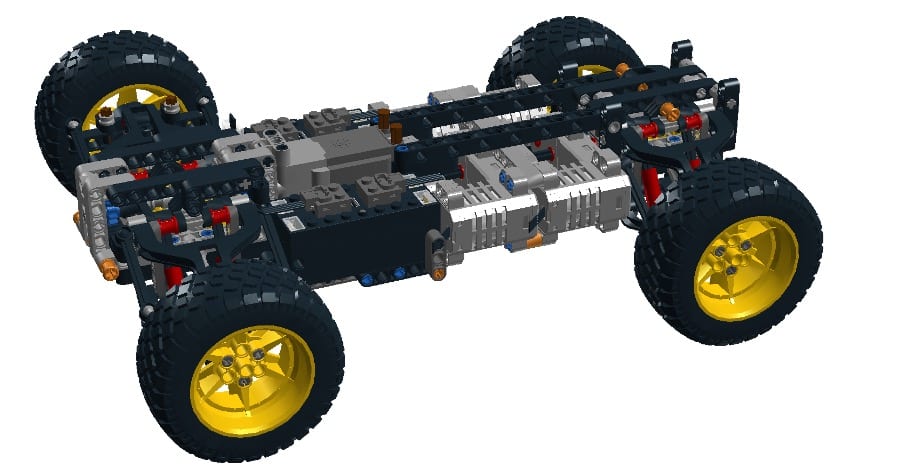

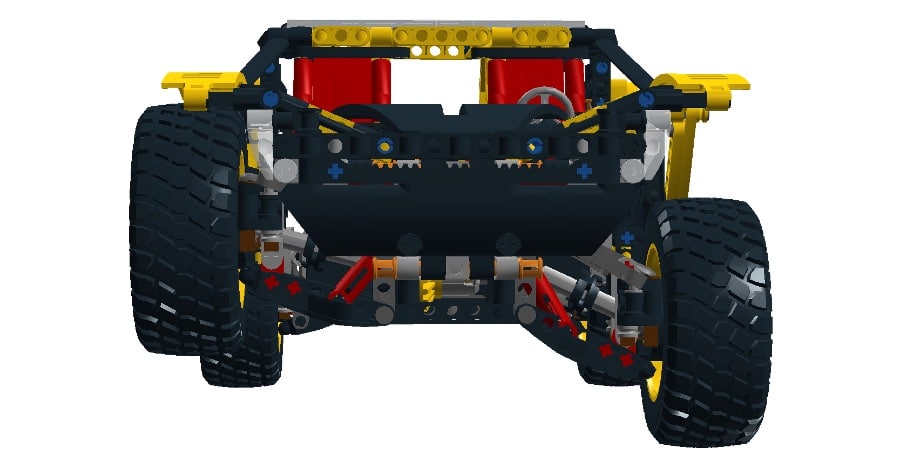

With the goals and improvements I set for myself before, I quickly came up with a prototype chassis that used only around 420 parts. Notice how all the heavy components, such as BuWizz bricks and motors, are placed as low as possible. A big contribution to the low part number is the usage of various frames and flips flop beams, which increase the stiffness of the chassis, while keeping the weight low:

I decided to use the newly available tyres from 42177 G-500 as they provided the best compromise of size, off-road tread and low rolling resistance. Compared to the 107 mm tractor tires used on the 4×4 Trophy Truck, these run much smoother and leave more space for steering arms.

3. Building the physical model – suspension system

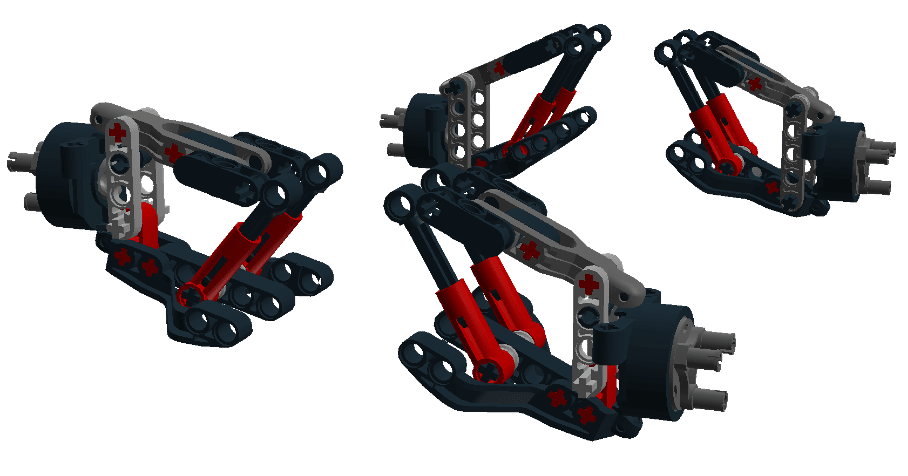

After building the first chassis from real parts, I quickly discovered that I had to tweak and improve the suspension system. The 4423 suspension arms used are very prone to bending inwards and outwards, so I had to reinforce them with beams. The upper suspension arms were replaced with a brick build solution due to the limited space available. Here’s how the final version of the suspension system looks like:

The biggest feature of the suspension system is the placement of the shock absorbers. Not only are they fully integrated inside the suspension arms, but they also provide a very unique solution. Each suspension arm uses 2 normal sized hard shock absorbers, which are placed at an angle. The more the suspension arm compresses the shock absorbers, the more perpendicular they are to the said suspension arms. This geometry progressively increases the hardness of the suspension system. This means that the suspension system is at first soft, but then gets progressively (non-linearly) harder to absorb large jumps.

4. The steering system

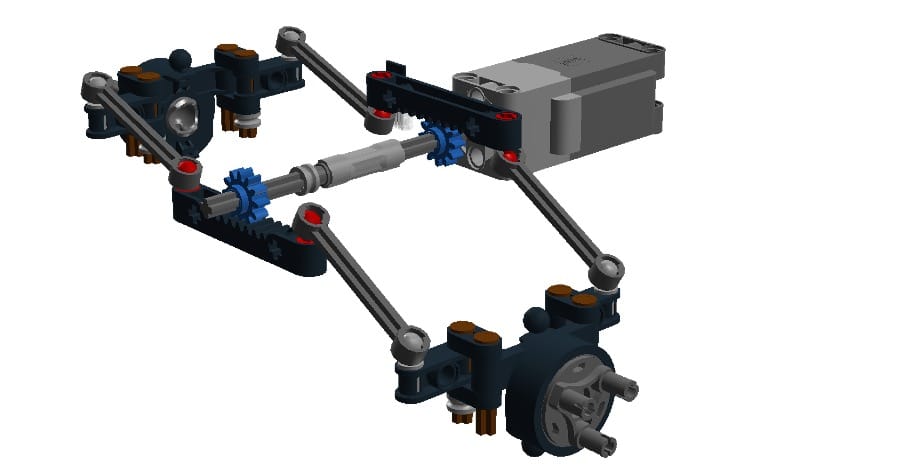

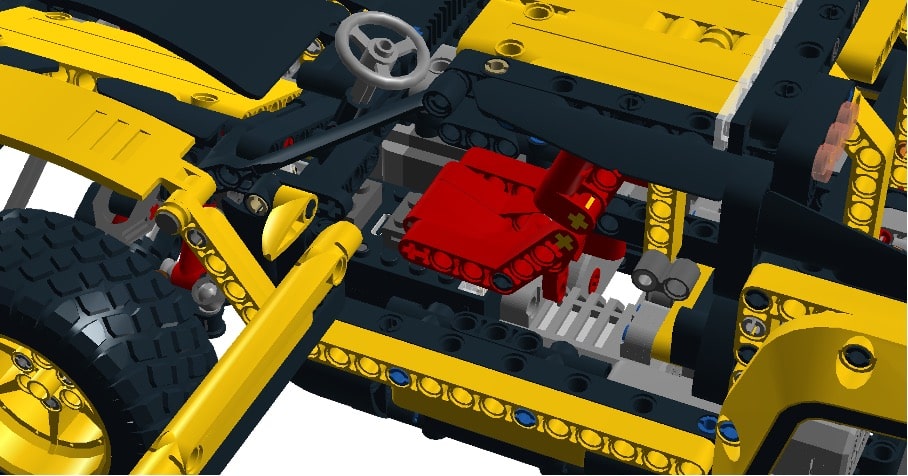

The steering system was improved by extending the steering arms and motorizing both steering racks. Another improvement is the use of blue 69778 gears which reduce the slack and increase the steering range of the steering racks:

A detail worth mentioning is that I intentionally used 7 stud long suspension arms and 6 stud steering links in order to add a slight pretension to the steering system, thereby reducing slack. This improved steering system gives the Dakar Racer around 25 degrees of steering angle while being much more accurate, robust and reliable than the one used in the 4×4 Trophy Truck.

5. Driveline

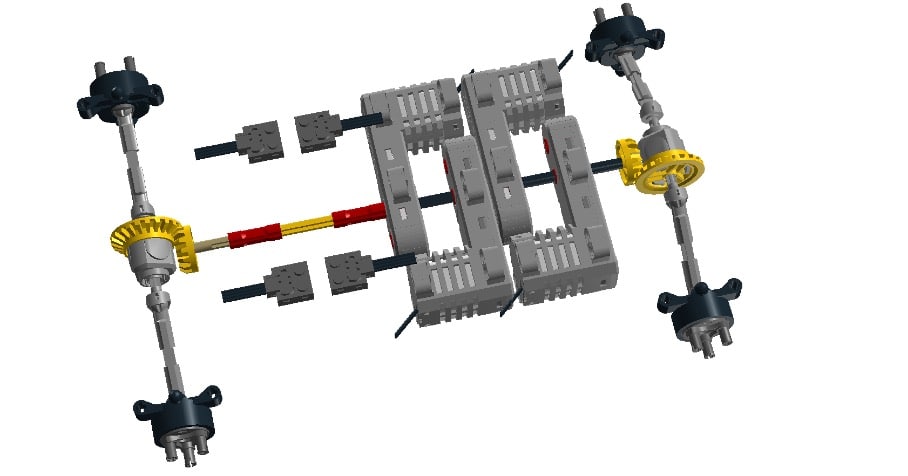

The driveline is also very different from the 4×4 Trophy Truck. Instead of each motor powering each wheel, all 4 motors are hard coupled together so that full power can be sent to either axle. The only gears used in the driveline are the yellow reinforced differentials as you can see here:

In the 4×4 Dakar Racer the front wheel drive motors could not help the rear wheels when climbing uphill, the wheels would simply free spin. Dakar Racer having all the motors coupled together to power all the wheels improves performance, especially when climbing uphill and over obstacles.

6. Aesthetics and ease of access

With the suspension, steering and driveline completed, I turned my focus to the aesthetics. I wanted to use the readily available parts I had left from previous sets/projects. Recently parted out 42114 Articulated Volvo hauler proved to be a great part donor for the wheels, wheel arches, fenders and other panels:

My main focus was to give the model organic shaping, while keeping the body strong enough to survive crashes and rolls. An example of this is the LED bar on top of the roof. It’s not just for decoration, but it also keeps the roof from coming apart.

Regarding aesthetics, I really wanted to emphasize the low profile. An example of that is the hood that starts very low in the middle and lifts above the wheels with just enough space to accommodate the wheels when the suspension is fully compressed:

The interior was decorated with 2 seats and a steering wheel. Unlike the 4×4 Trophy Truck, the whole body can’t be removed, but the doors can be opened instead. The steering wheel can be tilted up in order to access the BuWizz 3.0 Pro for charging:

The rear section has been left open, not only to keep the weight low, but to keep the chassis partially visible. I really wanted to have a bit of the chassis visible to show just how low, compact and functional the modern Technic system can be. Also notice the use of diagonal braces and flip flop beams to hold the rear wheels arches firmly in place:

With the bodywork and interior completed, the total part number reached around 900 parts – well below the goal of 1000 parts. On paper this model is therefore lighter and has a slightly higher power/weight ratio compared to the 4×4 Trophy Truck even though it uses fewer motors and BuWizz bricks. All that was left was to test it and record it in the wild.

7. Fixing the driveline

During video recording, I discovered a fault in the driveline system. There was just enough slack for the CV joints to slightly pull out of the differentials, damage the 12 tooth bevel gears and start slipping. In order to fix this issue, I added a 2×2 round brick and a 2×2 round tile, which reduced the slack on the drive shafts and the issue was solved.

I hope you enjoyed this blogpost as much as I have been designing, building and pushing this model through its paces.

To conclude, this was not only a real fun project, but also a good design lesson. And if you want to build it, learn more about it and play with the model yourself, you can download the complete instruction guide here:

Enjoy!

Article written by Jernej (Zerobricks)